Cat:RO Membrane

Specification and size: ULP-4040; ULP-8040 Reverse osmosis (RO) membranes are vital components in water filtration systems, particularly in desalinat...

See Details1. Core Principles of Ultrafiltration Technology

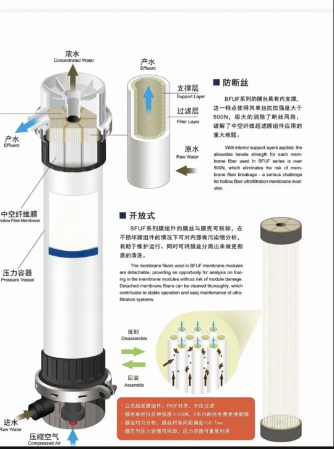

Ultrafiltration water treatment is a membrane separation technology between microfiltration and nanofiltration. It uses pressure differentials as a driving force, utilizing hollow fiber membranes with pore sizes of 0.01-0.1 μm to intercept colloids, bacteria, viruses, and some organic matter in water. Its core advantages are:

Physical screening mechanism: no need to add chemical agents, avoiding secondary pollution

Normal temperature operation: energy consumption is only 1/5-1/3 of reverse osmosis

High retention rate: bacterial removal rate > 99.9%, turbidity removal rate can reach below 0.1NTU

2. Four key parameters for ultrafiltration equipment selection

(1) Membrane material selection:

Polyvinylidene fluoride (PVDF): strong pollution resistance, suitable for industrial wastewater treatment

Polyacrylonitrile (PAN): good hydrophilicity, commonly used for drinking water purification

Polyethersulfone (PES): chemical stability, can withstand pH environment

(2) Membrane component form:

Internal pressure type: raw water flows from the inside of the membrane to the outside, suitable for high turbidity water quality

External pressure type: raw water flows from the outside of the membrane to the inside, with stronger pollution resistance

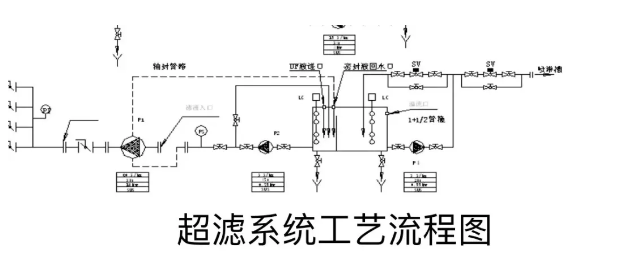

3. Industrial ultrafiltration system operation and maintenance practice

(1) Three elements of membrane pollution control :

Pretreatment process: The front end needs to be equipped with a multi-media filter + activated carbon adsorption to reduce the SDI value to <5

Cross-flow filtration: Maintain a membrane surface flow rate of 2-3m/s to reduce pollutant deposition

Periodic backwashing: Perform air-water washing once every 30-60 minutes, and the backwash pressure is <0.2MPa

(2) Chemical cleaning solution:

| Contamination Type | Cleaning Solution Formula | Cleaning Time | Temperature Control |

| Organic Matter | 0.5–1% NaOH solution | 40–60 min | 30–35°C |

| Inorganic Matter | 1–2% HCl solution | 30–45 min | Ambient temperature |

| Microorganisms | 0.1% NaClO solution | 60–90 min | 25–30°C |

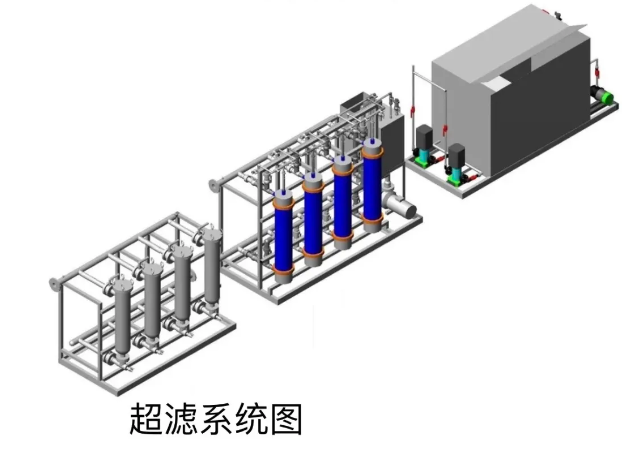

4. Typical application scenarios

(1) Municipal water supply deep treatment: The water plant adopts the "conventional treatment + UF" process, and the turbidity of the produced water is stable <0.05NTU and the total bacterial count is <1CFU/mL

(2) Industrial wastewater reuse: After the oily wastewater from the electronics factory is treated by the "UF+RO" double membrane method, the reuse rate reaches 85% and the COD removal rate is >92%

(3) Emergency water supply guarantee: The earthquake-stricken area uses a vehicle-mounted ultrafiltration equipment, with a daily processing capacity of 500m³ per unit, which can meet the drinking water needs of 10,000 people